What is Optifye.ai?

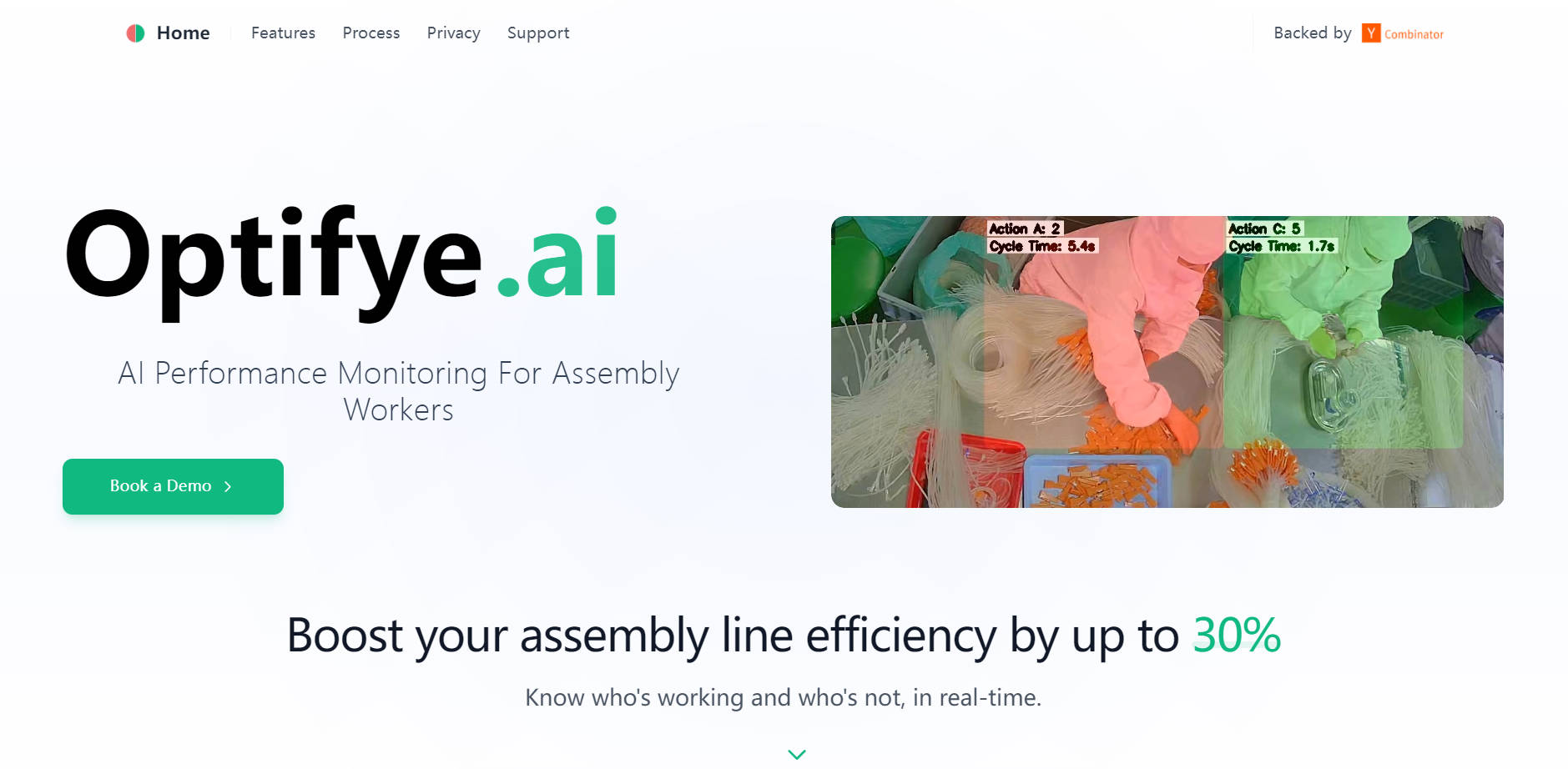

In manufacturing, understanding the performance of your assembly line is crucial for efficiency and profitability. Optifye.ai offers a solution to the "black box" of the shop floor, providing real-time insights into worker activity and output. By leveraging AI-powered computer vision, Optifye.ai helps you identify bottlenecks, optimize processes, and boost your line efficiency by up to 30%.

Key Features:

👁️ Monitor Worker Activity in Real-Time: Instantly see who is actively working and who is falling behind target output. This allows for immediate intervention and support where needed.

📊 Measure Precise Output: Obtain accurate, worker-specific and line-specific output counts, eliminating the inaccuracies of manual tracking.

⏱️ Analyze Cycle Times: Accurately measure the production cycle time at each workstation, providing valuable data for process optimization.

⚠️ Detect Bottlenecks: Identify production bottlenecks and system inefficiencies by analyzing the performance of each workspace. This enables targeted improvements to streamline workflow.

📝 Receive Automated Reports: Get daily updates delivered directly via WhatsApp and email to management, plant heads, and supervisors, keeping everyone informed of key performance metrics.

💡 Discover True Production Potential Manufacturing companies often operate significantly below their potential. Optifye shows you the ideal yield, helping you to understand the gap.

Use Cases:

Proactive Intervention: A supervisor receives a real-time alert that a worker on Line 3 is consistently falling behind the target output rate. The supervisor can immediately investigate the issue, provide assistance, and prevent further delays, minimizing lost production time.

Data-Driven Process Improvement: After a week of using Optifye.ai, a plant manager notices that Workstation 5 consistently has the longest cycle time. This data reveals a bottleneck. The manager can then investigate the cause (e.g., inadequate training, equipment malfunction, inefficient workflow) and implement targeted solutions.

Shift-to-Shift Performance Comparison: A manufacturing company uses Optifye.ai's automated reports to compare the output and efficiency of different shifts. This data can reveal best practices, identify areas for improvement, and inform staffing decisions.

Conclusion:

Optifye.ai provides the visibility and data you need to transform your assembly line operations. By understanding worker performance in real-time and identifying areas for improvement, you can unlock significant gains in efficiency and productivity. Optifye.ai empowers you to move from guesswork to data-driven decision-making.

More information on Optifye.ai

Top 5 Countries

Traffic Sources

Optifye.ai Alternatives

Load more Alternatives-

Invisible AI – is an on-premise computer vision platform that captures data from manual assembly work and uses AI to make smart recommendations.

-

Streamline sales operations, boost sales effortlessly, and optimize revenue potential with OptimateAI. Get paid faster and automate accounts receivables with just 2 clicks. Take your business to the next level now!

-

-

Accelerate engineering & compliance with Optimal AI. Automate code reviews, boost security, get productivity insights. Zero data retention.

-